1. Material Characteristics

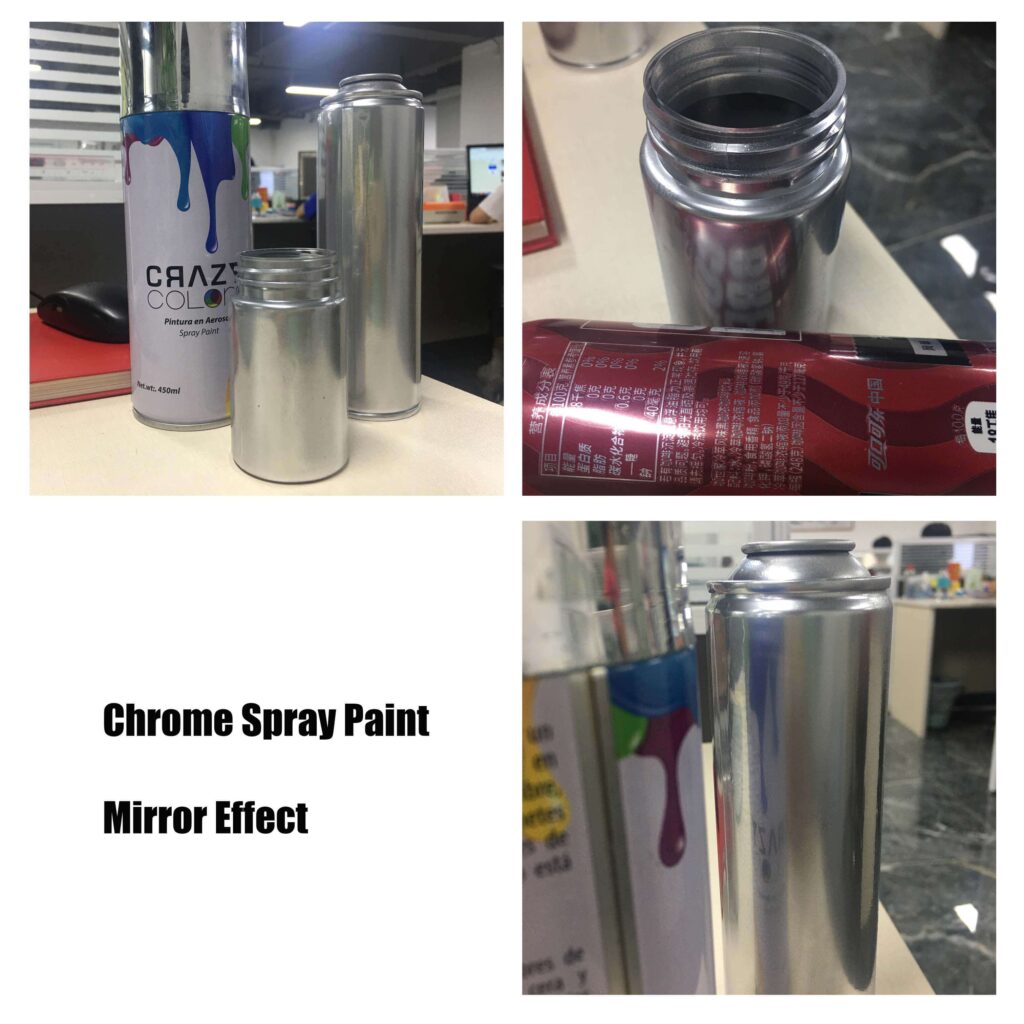

Chrome Spray Paint

•Composition: Spray paint is a coating based on acrylic or polyurethane resins, mixed with metallic powders (e.g., aluminum) to create a reflective effect resembling chrome plating.

•Thickness: The coating is very thin, usually at the micron level, serving primarily as decoration.

•Adhesion: Relies on primer and surface treatment, prone to peeling or scratching.

Electroplated Chrome

•Composition: Metal chromium is electroplated onto the surface of an object through an electrochemical process, forming a uniform metallic layer.

•Thickness: The thickness of the electroplated layer typically ranges from 0.25 to 20 microns, depending on application requirements.

•Adhesion: Strongly bonded to the substrate, offering superior durability.

2. Process Differences

Chrome Spray Paint

•Application: Directly sprayed onto the wheel surface; quick to complete.

•Equipment Requirements: Does not require complex equipment, suitable for small-scale applications.

•Cost: Lower, considered a budget-friendly solution.

Electroplated Chrome

•Application: Involves multiple steps, including degreasing, polishing, and electroplating.

•Equipment Requirements: Requires specialized electroplating equipment and strict operating conditions.

•Cost: Higher, but delivers professional and long-lasting surface treatment results.

3. Effect Comparison

Appearance

•Chrome Spray Paint: Produces a mirror-like effect but lacks the luster and reflectivity of real chrome plating. While it may appear similar from a distance, details are noticeably inferior.

•Electroplated Chrome: Offers deep, uniform mirror-like reflection, with a high-end visual quality.

Uniformity

•Chrome Spray Paint: May exhibit color inconsistencies or uneven coverage, particularly on complex geometric shapes.

•Electroplated Chrome: Achieves uniform layer distribution, adapting to complex shapes with a flawless surface.

4. Durability

Chrome Spray Paint

•Wear Resistance: Easily scratched and not resistant to heavy abrasion.

•Oxidation Resistance: Tends to fade or bubble when exposed to outdoor or humid environments.

•Corrosion Resistance: Poor weather resistance; prolonged use may result in peeling.

Electroplated Chrome

•Wear Resistance: High hardness (chromium has a Mohs hardness of 8.5), resistant to daily scratches.

•Oxidation Resistance: Strong resistance to air and water corrosion.

•Corrosion Resistance: Suitable for various harsh environments, such as salt spray and muddy water.

5. Application Scenarios

Chrome Spray Paint

Ideal for:

•Short-term decorative needs: Such as exhibition displays or infrequently used items.

•Budget-conscious projects: For example, surface decoration of non-critical components.

•DIY enthusiasts: A cost-effective way to experiment with visual changes.

Electroplated Chrome

Ideal for:

•Long-term durability: Such as car wheels, motorcycle parts, and other high-use components.

•High-end visual appeal: For luxury vehicles or custom modifications.

•Environments with high weather resistance demands: Such as coastal areas or winter regions with heavy salt use.

Summary: Why Spray Paint Cannot Replace Electroplating

1.Durability Gap: Spray paint is vulnerable to environmental effects, whereas electroplated layers provide lasting protection.

2.Visual Quality: Spray paint cannot replicate the deep gloss and reflectivity of chrome plating.

3.Different Use Cases: Spray paint is better for short-term decoration, while electroplating is the long-term solution.